WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

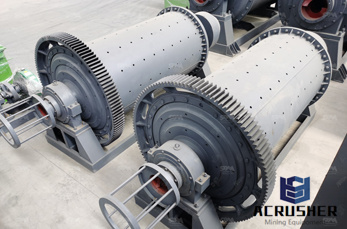

Works, India. We are special because We can make customised gear as per drawing casting gear. We are manufacruting & supply girth gear in various application. like girth gear for Vertical Roller Mill, Vertical Raw Mill, Vertical Coal Mill, GGBS Vertical Roller Mill, Vertical Cement Mill, Ball Mill, Raw Mill Girth Gear, Raw Meal Ball Mill, India's Rotary Kiln Spare parts ...

Various types of vertical mills exist to grind limestone, coal and cement clinker. Regardless of the type you finally decide on: our combined industrial gear units are always a reliable drive solution.

Manufacturer of Coal Mill Or Plant machinery parts Rotary Kiln - Girth Gear, Heavy Duty Gear, Rotary Kiln Tyres and Kiln Girth Gear - Spur - Helical Gear - Mill Gear offered by SEW Gears.

Filter: advanced process control air pollution control ball mill ball mill drive cement cement grinding cement production cement rotary kiln clean clinker cooling co2 emission coal grinding ecs/processexpert expert system fabri fabric fabriclean filter flsmidht fl fl maag gear fl; energy efficiency gas gear overhaul gearbox ...

Rod mill is asynchronous motor through the gear reducer and small gear coupling, turns around the big gear reduction, directly driven rotary rotary, barrel inner is equipped with the appropriate grinding medium - steel rods, grinding medium under the action of centrifugal force and friction force, to manufacture materials by feeding department continuously into the barrel inside, are ...

Jun 2, 2019- Explore Andrew Meshel's board "Milling projects and ideas", followed by 251 people on Pinterest. See more ideas about Tools, Metal working tools and Bricolage.

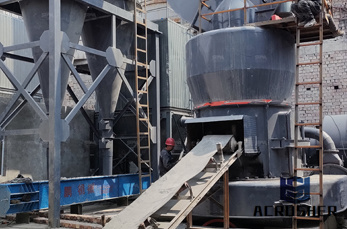

Vertical mills are mainly used for comminuting ores, limestone, clinker, slag, lime, gypsum, and coal in coal beneficiation plants. They reduce raw material from a thickness of 30 mm to a very fine-grain. The pulverizing of mineral raw materials is an extraordinarily energy-consuming process. To make .

A wide variety of vertical gearbox options are available to you, such as worm, helical, and bevel / miter. There are 16,197 vertical gearbox suppliers, mainly located in Asia. The top supplying countries are China (Mainland), Taiwan, and India, which supply 99%, 1%, and 1% of vertical gearbox respectively.

Jun 16, 2013· Hey Guys, This is a LOT to ask, but I address it to those of you with experience making GEARS on your manual milling machines using a dividing head. Is there anyone out there willing to do a photo-essay on how to make a stud gear, or other replacement gear for your lathe using a manual milling machine?

Houston Pump & Gear Service Center. At Houston Pump & Gear, we appreciate your interest in our company. Houston Pump & Gear provides mechanical equipment repairs, restoration services, gears, gearboxes and other related products, since 1998. We have experienced tremendous growth over the past years as the result of the commitment we have to customer service.

Vertical mills (such as bowl, roller grinding, ball-and-ring, and roller mills) are mainly used for comminuting limestone, clinker, slag, lime, gypsum, and ores for the building industry, and coal in the coal preparation. They reduce raw material from a thickness of 30 mm to a very fine-grained material.

• Gear Reducers, Feeders, Exhauster Fans and Liners. • Other Spares Parts & Components All Wabash reconditioned mills and equipment are properly packaged for shipment. Check out our inventory below and give us a call for a fast quote. Bowl Mills Roller Mills Impact Mills Vertical Mills Commitment to Quality. Wabash stands behind our work.

DFMEA of a Roller Mill Gear box. Article ... levels of effects of failure and corrective actions to be taken in the design phase for Bevel-Planetary Vertical Roller Mill Gearbox.

This is why the special requirement made on a gear unit for vertical mills is its reliability. And for this reason, the worldwide tried and tested bevel planetary gear units (Flender KMS, KMP, KMPS, and KMPP) are top quality to many operators of vertical mills, in particular, when a cost-optimized constant-speed drive is required.

Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800's. These early machines were the forerunner of the heavy-duty, rugged ring-roll mill manufactured today. The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materials.

Next Page→. This tutorial will show you how to make gears with your CNC Machine using both Sketchup and CAMBAM. Even if you have no idea what a CNC is, this page will still be useful even if all you really want to do is draw a gear in Sketchup.

go to the home page go to the page above this one "helical gears - links" Making helical gears on a vertical milling machine. It is pointed out elsewhere that most amateurs will not have a suitable horizontal milling machine for making helical gears. However it is just as easy to make helical gears .

go to the home page go to the page above this one Making helical gears on a horizontal milling machine This is really just the same as making helical gears on the vertical milling machine. The full description is to be found:: see making helical gears on a vertical milling machine Only .

SEW Gears - offering Kiln Support Roller, सपोर्ट रोलर at Rs 250000 /number in Ghaziabad, Uttar Pradesh. ... Cement Plant Machinery, Vertical Roller Mill, Vertical Raw Mill, Vertical Coal Mill, GGBS Vertical Roller Mill, Vertical Cement Mill, Ball Mill, Raw Mill Girth Gear, Raw Meal Ball Mill, India's Rotary Kiln Spare parts ...

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blast-furnace slag with small to medium output rates, the MVR mill with conventional drive is .

Ulf Weller, Senior Design Engineer, MAAG Gear AG Rocco Amato, Head of Mill Gear Engineering, MAAG Gear AG Drive trains of vertical roller mills are usually equipped with heavy duty gearboxes with a horizontal input shaft and a vertical output shaft. Increasing mill sizes bring the existing gearbox concepts to their limits, however.

Vertical mill; Show/hide breadcrumbs Vertical mill. Various types of vertical mills exist to grind limestone, coal and cement clinker. Regardless of the type you finally decide on: our combined industrial gear units are always a reliable drive solution. Robust and customised drive solutions for vertical mills ...

Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a direct-fired coal burning system.

The Problem - Coal fired power plants typically operate several ball mills or coal pulverizing mills to crush the incoming coal to the optimum size for combustion. This means that each power generation unit has five or six mills. The gearboxes that run these coal mills are usually lubricated with high viscosity oil, such as ISO VG320 or ISO VG460.