WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

vertical roller mill operation and parameters. Vertical Roller Mill Operation. Vertical roller mill is widely used in the cement industry raw materials, clinker preparation, grinding slag, ore, industrial silicon, carbide slag, coal gangue and coal chemical industry, power plant desulfurization, coal preparation and other areas of high ...

vertical impact mill pdf in malaysia . operational parameter for vertical roller mill +pdf operational parameter for vertical roller mill +pdf south Africa Philippines Brazil canada Malaysia Impact crusher Grinding Mill| Grinding Mill Solution-Raymond Mill Roller SCM Super-micro Mill Vertical Roller Mill etc The second serie is the stone crusher series including Jaw Crusher JC Jaw Crusher ...

The vertical roller mill has two classic models, namely the LM series vertical .... between the three, play the best process parameters of vertical grinding mill. Get Price 2004 MPS vertical roller mills for gypsum Global ...

Mar 07, 2013· LM-Master for Vertical Roller Mills 1. FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, .

Grinding roller is core part of vertical mill. SYMMEN METAL Casting can provide customized service according to customers'different processing requirements. Besides, it provides finished product manufacturing service for grinding roller .

Vertical Roller Parameters - archedyleu. vertical roller millparameter - evdara vertical roller mill,parameter Operating experience with a vertical roller mill for grinding,vertical roller mill,parameter,Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite, This article focuses on way the grinding aids affect .

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to. maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited.

vertical roller mill operation process. Process Parameters Vertical Roller Mill vertical roller mill operation and parameters -Coal If you are looking to buy mining processing equipment you got to Get Price Vertical Roller Mill Operation Hot Crusher Vertical Roller mill is an ideal large-scale grinding equipment Vertical Roller .

Grinding roller is core part of vertical mill. SYMMEN METAL Casting can provide customized service according to customers'different processing requirements. Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc. We gained good reputation from customers.

CLUM vertical roller mill is our new technology stone powder grinding mill machine can be used in more than 300 kinds of minerals powder grinding. And the powder Fineness made by the CLUM vertical roller mill can be adjusted between 600-3000 mesh. Take calcite powder grinding as an example what s parameter of our CLUM vertical roller mill

vertical roller mill, parameter. vertical roller mill,parameter greenrevolutionorgin. Vertical roller mill, Vertical roller mill introduction, Vertical mill manufacturers Parameters Vertical Roller Mill is a new kind of large scale power mill which is designed specially to solve the problems of low capacity and high consumption of industry mills.

LM fine vertical roller mill. New fine vertical roller mills is developed by our company, it create a particle size distribution with a sharper cut in comparison to cement milled in a traditional ball mill, the compact design allows it to dry, grind and classify, all within one .

Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill .

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA LMmaster_forVRMsdd 1 .

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill .

Mar 01, 2016· re vibration vertical roller mill. There are a number of reasons for high vibrations in vertical roller mills, such as: 1. Failure of the grout or cement material under the steel beams .

LUM ultrafine vertical roller mill is mainly composed of a motor, reducer, roller grinding device, disk device, compression body device, separator, and gas station etc.. Idea of reality and it is turned out that complete the ultrafine powder grinding, grading and conveying operation, the process parameters, mechanical properties and refined ...

Grinding system/Vertical roller mills KTM EN 07/2012 The producer reserves the right to modify products and/or their parameters without previous notification. ©2012 PSP Engineering a.s. PSP .

Apr 01, 2017· In this study, pilot scale tests were performed with a mobile vertical-roller-mill grinding plant to investigate the relationships between operational parameters. The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational vertical-roller-mill performance model.

Design A Vertical Roller Mill. Every solution-make is the effort of all our Workers, Engineers and Professionals ... This article will discuss the methodology for the calculations of belt conveyor design parameters .

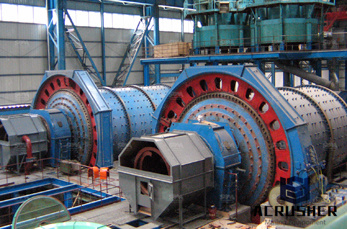

The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation.

Operational parameters affecting the vertical roller mill. Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium. Milling Process, Defects, Equipment. The spindle is located inside the milling head, which is ...

Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding ...

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.