WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The commonly used grinding media in the ball mill is grinding steel balls and grinding bar. We will provide proper product model and grinding way according to the features of the materials and your requirements. Our ball mill has full models for sale, you can choose the proper model according to .

Working Principle When the ball mill rotating, as the centrifugal force, the grinding media will attach on the grinding mills inn er wall, and rotating with the grinding mill, as itself gravity, it will fall like projectile, so break the materials in the tube.

Grinding Media Selection Guide | Union Process®, Inc. How to Select Grinding Media Forms Literature, The type of mill also can affect the selection of grinding media Ball Mills use very large media while Attritors . [24/7 online]

Jul 22, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Canada's best source for Quality Tools, Equipment and Supplies for Jewellers and the Jewellery Industry. Over 17,000 products available from our 16,000 SF warehouse in Toronto. In-stock orders placed before 3:30pm shipped the same day. Can't find what you are looking for? Call our highly trained customer service reps at 1-800-263-6106 who will be more then happy to find the right solution for ...

media shape and mill power. The objective of this dissertation was to investigate how media shape affects grinding. Ball size distribution inside an industrial mill was analysed in terms of shapes and sizes. Load behaviour, mill power and breakage as affected by media shapes were studied in a pilot laboratory mill. An inductive proximity probe ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Dec 08, 2009· Re: how to estimate the wear rate for Ball mill. Most practical way to by measuring empty height and calculating the % volumetric filling of grinding media.Alternative way to make track of mill main drive kW consumption reduction and add makeup .

how to calculate grinding media for 1830*7000 mill - Grinding ... » how to calculate grinding media charging size » grinding media ball for cement » ceramic ball mill media ratio » alumina ceramic grinding beads:pdf » Learn More. HOW TO CALCULATE GRINDING MEDIA SIZES FOR BALL MILL - .

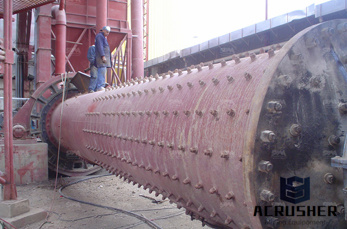

Rod mills are grinding machine which employ high carbon steel or special steel rods of nearly the same length as that of the drum, in place of steel balls in ball mills. Rod mill products are generally coarser than those produced in a ball mill, and rod mills are well suited to handle coarser feed and to control the top size of the product.

Steel Ball Mill The steel ball mill contains a neoprene barrel that has grinding media in it. The material to be ground is loaded into this barrel. The barrel of the steel ball mill rotates at a specific speed causing the crushing of the material to powder form by the individual pieces of the grinding media.

Chatter in Machining: Milling & Lathe Vibration [ Lesson 14: F&S Email ] Note: This is Lesson 14 of our Free Email Feeds & Speeds Master Class. Click here to learn more about the Master Class. I Need to Solve a Chatter Problem Right Now! If you found this page because you have a problem with chatter in machining right now and not because you're reading through our Cookbook or are just ...

The FC Bond Work Index Test Ball Mill was designed by F. C. Bond for use in determining the Bond Index, a measure of grindability and power required for grinding applications. The FC Bond Mills are used in laboratories throughout the world. A copy of Fred C. Bond's Method of Crushing and Grinding for determination of the Bond Index is included with each mill.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (e.g., via a hand crank), working animal (e.g., horse mill), wind or water ().

Prices and Wages by Decade: 1840-1849. ... foundry laborers, lathe hands, machinists, millwrights in flour mills and other places, iron molders, pattern makers, tool and die makers. Mining -- Coal mine and iron mine industries, 1840-1900 ... Provides explanations and charts to help users calculate the current value of historic dollar amounts.

Application: Energy saving mining ball mill is a key equipment in beneficiation plant.It is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materials.

Brief Introduction of Ball Mill Grinding: Ball mill Grinding can divide into 2 types, wet ball mill grinding and dry ball mill grinding. Ball mill grinding is a mineral processing machine for milling the materials into powders after they are crushed. It

Figure 8.2 Media motion in the tumbling mill. 8.1 Grinding 8.1.1 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types - rod, ball, pebble autogenous and semi-autogenous. The grinding action is induced by relative motion between the

Ball Mill Wearing Parts: Ball Mill Wearing Parts:bull gear,pinion gear,main bearing,reduction box bearing,reduction box,gear shaft,bearing,and scale board. Working principle of Ball Mill: Ball mill grinding is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill ...

MTW european grinding mill. Message. Get Price. JC series jaw crusher. Message. Get Price. CI5X series impact crusher. Message. Get Price. Buderus Grinding Machines Germany Buderus-Schleiftechnik.DVS-Gruppe > Get an overview of our complete line of machines. Use the navigation feature to filter your list of results.

G-Wizard's feed and speed calculator is designed to help you determine the best feeds and speeds for particular machining operations. Getting the best feed and speed for your particular tooling and cutting situation is one of the most important steps to ensure maximum material removal rates, best surface finishes, and better tool life.The Feeds and Speeds calculator considers many additional ...

The Pigeon Forge Mill, commonly called the Old Mill, is a historic gristmill in the U.S. city of Pigeon Forge, Tennessee.Located along the West Fork of the Little Pigeon River, the mill complex currently consists of a millhouse, breastshot wheel, and milldam, all of which are operative. The mill is the only structure in Pigeon Forge listed on the National Register of Historic Places.

Mill (grinding) - Wikipedia. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them.

Steatite ceramic ball mill lining bricks and grinding media The true value of mill lining and grinding media is measured by length of trouble free service in relation to its production output. Jyoti Ceramic's Steatite grade HF 82 ceramic composite corresponds to German Steatite ceramic grade KER 221 . .