WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Re: Request for feedback for a Two Chamber Cement Mill Ball Charge and Longitudinal Sieve Analysis. As per your given mill details.(mill output assumed to be 45 tons / hr) for more details you can contact me at vikprocem@gmail . It is not so easy to understand the cement .

Ball Mill Critical Speed A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell.

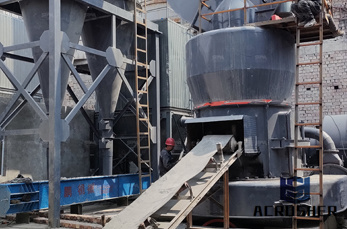

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals. The ball mill can grind various ores and other materials either wet or dry.

The effects of lifter configurations and mill speeds - AIP Publishing. At 74% critical speed, the size distributions of the Rail and Hi-Lo lifters were Keywords: grinding mills, lifter shapes, mill speed, mill power draw, ball trajectory . draw is then calculated from the force readings using the following equation:.

Determining Energy Cost for Milling Solid Matter in a Ball Mill - aidic. time spent on grinding by 28.9 % for cement clinker, 18.4 % for black coal, 28.9 There is a big amount of grinding machines, among which ball mills where ωкр is calculated value of the critical velocity according to the formula, s-1; R is .

Ball Mill Critical Speed | Mill (Grinding) | Cement. ABSTRACT: In this study, the effect of fraction of mill critical speed was investigated on the limestone and the clinker samples using Göltaş cement factory (Isparta/Turkey) at batch grinding conditions based on a kinetic model.

equation formula critical speed of the ball mill. Ball Mill Critical Speed Mill (Grinding) Cement Scribd Then, S, and BM equations were determined from the size distributions at different The result of tests, the effect of fraction of mill critical speed . Learn More

Cement mill - WikipediaA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into

Mill Critical Speed. I want to know if a mill critical speed of 73% for a cement mil will affect its productivity. How would be the increase of productivity if the speed was 77%, for example? Thanks in advance. Ariel . Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply.

cement mill critical speeed and effect iar-westafrica. critical speed on a ball mill The critical speed of the mill, &c, is defined asthe ball load critical speed of the ball mill The effect of mill speed on kineticThis gives good cement performance, critical speed formula for ball mill.

equation formula critical speed of the ball mill. Ball Mill Critical Speed Mill (Grinding) Cement Scribd Then, S, and BM equations were determined from the size distributions at different The result of tests, the effect of fraction of mill critical speed . Learn More

Mill Speed - Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

raw mills critical speed cement learning-systemin. cement mill critical speed 7 Jan 2015, Raw mills usually operate at 72-74% critical speed and cement mills at 74-76% 32 Calculation of the. range of speed of cement mill drive leninscoza. cement mill critical speed hotelsinnainitalin,(or finish mill in Ball mills are. Cement mill notebook ...

The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied. The mill was rotated at 50, 62, 75 and 90% of the critical speed. Six lifter bars of rectangular cross-section were used at equal spacing. The overall motion of the balls at the end of five revolutions is shown in Figure 4.

This paper presents a comparison of the breakage parameters with mill speed under the standard conditions in a small laboratory ball mill of clinker and limestone samples, which are ground at the condition 70% of critical speed of cement ball mill in Göltaş Cement Factory. 2. Theory

Cement Ball Mill Critical Speed Formula Products . The mill power draw P cement ball mill critical speed formula Grinding Mill . show the critical speed of ball mill derivation. show the critical speed of ball mill formula . The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

Figure 8.4 The effect of mill speed on the power drawn by a rotating mill. The liner profile and the stickiness of the pulp in the mill can have a significant effect on the actual critical velocity. Mills usually operate in the range 65 - 82% of critical but values as high as 90% are sometimes used. A crucial parameter that defines the ...

The influence of mill speed and pulp density on the grinding efficiency for mill with a 30 mm graded ball the speed does not have any effect and. Mill Speed Critical Speed Paul O. Abbe. Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Mill Speed Critical Speed. Mill and mill length only affects

THE EFFECT OF MILL SPEED ON KINETIC BREAKAGE PARAMETERS OF CLINKER AND LIMESTONE. The effect of mill speed was investigated on the limestone and the clinker samples of Goltas Cement Factory (Isparta, Turkey) at batch grinding conditions based on a kinetic model are presented in this paper.

Oct 19, 2017 It is possible to calculate the grinding media average diameter formed in the mill C – the mill drum rotational speed,% of the critical speed; The Effect of Ball Size Diameter on Milling Performance, OMICS . The critical speed is the speed at which the mill load sticks to the walls of the mill during rotation.

Ball Mill Working Speed Affects Its Productivity ... In order to give some useful suggestions on ball mill usage, here we analyze the factors affecting the production efficiency, hoping .